At thyssenkrupp Materials NA Canada, we have a wide range of high-quality engineering plastics and high-performance plastic stock available. Choose from a variety of plastic sheets, rods, tubes, and films for your next project. Take advantage of our custom cutting service to save production time. If you can't find what you need, feel free to get in touch with our experienced sales team today. We are ready to assist you.

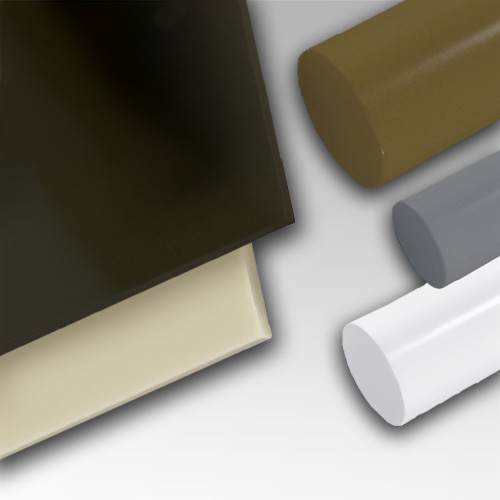

ABS

ABS, or acrylonitrile-butadiene-styrene, is a common thermoplastic that is easy to machine to close tolerances, easy to thermoform, and relatively low cost. The ease of machining and overall performance of ABS have made it one of the most popular materials for such wide-ranging applications as equipment housings, model making, storage bins and trays, and interior trim for vehicles and aircraft. thyssenkrupp Engineered Plastics / Online Plastics® is your #1 source for high quality ABS plastic sheet and ABS plastic rod at competitive prices. We offer ABS sheet in a range of grades in standard sizes up to 48” long and thicknesses up to 2”. We can cut-to-size to meet the dimensional requirements of your application. ABS sheet is available in black or natural colors and with a variety of surface textures. Our ABS rod is available in various grades in four standard lengths and a variety of diameters up to 5”. We can cut-to-length as needed. Black and natural colored ABS rod is available.

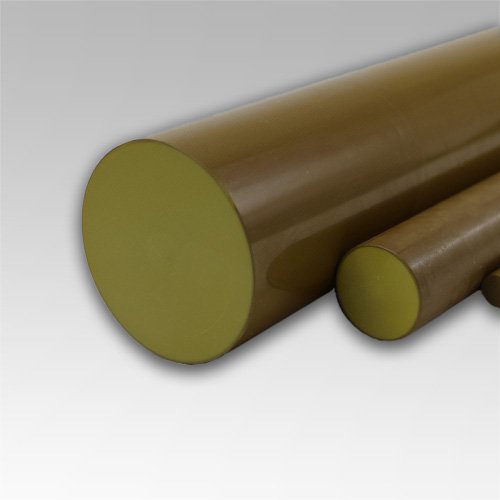

Nylon 30% glass-filled

Nylon 30% glass-filled is a high-performance composite material that combines the versatility of nylon with the enhanced mechanical properties of glass fibers. This results in a material with superior tensile strength, stiffness, dimensional stability, heat resistance, and wear resistance. It is widely used in demanding applications across automotive, industrial, electrical, consumer goods, and aerospace industries where high strength and durability are crucial.

Acetal

Acetal plastic, known for being machinable to precise tolerances, stands out due to its minimal moisture absorption, superior tensile strength, and low creep. Its physical properties stay constant even in temperatures soaring up to 180ºF. This resilience, coupled with its strong resistance to wear and abrasion, makes it ideal for a variety of applications. These attributes, combined with its durability, make Acetal plastic an ideal substitute for components conventionally crafted from metal, making it a preferred choice for applications demanding high performance and reliability.

Acrylic

Acrylic is an ideal alternative to glass in many applications. In addition to being half the weight glass and shatter resistant, acrylic is available in a variety of colors and coatings. Offering good weather resistance, acrylic does not warp, craze, crack, or corrode. Commonly used in a range of applications from signage, display boxes, lighting projects, and more in both industrial and manufacturing.

CelaZole

Celazole® PBI polybenzimidazole is an advanced, fully aromatic heterocyclic thermoplastic polymer that excels in both thermal and mechanical performance. With a remarkable glass transition temperature of 427°C, this material is engineered to deliver outstanding strength and broad-spectrum chemical resistance, making it particularly suitable for the most demanding environments. In addition to solid forms, PBI solutions are offered for specialized applications, including the production of hollow fiber membranes and flat sheet membranes. These solutions are also ideal for casting high-performance films or for coating metal surfaces, thereby extending the material's utility across a wide range of advanced industrial applications.

Cellulose Acetate Butyrate

Cellulose Acetate Butyrate CAB is a lightweight, soft and flexible plastic. CAB is easy to process due to its good dimensional stability, low shrinkage and water absorption. Commonly used for protective eyewear and face protection, consumer goods such as household items, signage and more. Available in clear sheets, CAB can be easily extruded, molded, and more to customize your need.

CPVC

CPVC, also known as Corzan® CPVC, is a high heat, corrosion resistant, chlorinated polyvinyl chloride material. CPVC displays excellent corrosion resistance at elevated temperatures and is ideally suited for self-supporting constructions where high temperatures are a concern. It is a long-lasting and high-quality product with a high resistance to chemicals that makes it ideal for use in chemical and mineral processing plants.

Delrin

DuPont™ Delrin® acetal homopolymer resin is a preferred choice for high-load mechanical applications like gears and conveyor belts across various industries. Replace metal components with low friction, high wear resistance, strength, and stiffness. Delrin® also has a broad temperature tolerance, ease of coloring, and compatibility with other materials. Offering superior tensile strength, stiffness, creep and impact resistance over acetal copolymer, it enables lighter and cost-efficient part designs and shorter manufacturing cycles.

Epoxy

Plastic epoxy is a type of adhesive known for its strong bonding capabilities and versatility. It consists of two main components: a resin and a hardener. When mixed, these components undergo a chemical reaction that results in a tough, durable, and high-strength bond. Because of its strength and versatility, it is a go-to choice for a wide range of applications, from household repairs to industrial manufacturing.

Ertalyte

Ertalyte ® is a brand name for a type of thermoplastic polyester known as polyethylene terephthalate PET-P. It is recognized for its excellent combination of mechanical and thermal properties, making it suitable for a wide range of industrial applications. It is a durable, efficient, and compliant material that is safe for direct contact with food, which expands its already wide range of industries to include food and beverage. There are two types of Ertalyte ®: Ertalyte ® TX and Ertalyte ® PET-P.

ETFE

ETFE is a versatile and high-performance fluoropolymer that excels in applications requiring chemical resistance, thermal stability, and durability. Its unique combination of properties makes it suitable for a wide range of industries, including architecture, aerospace, electronics, and chemical processing. Despite its higher cost, ETFE's exceptional performance characteristics make it a valuable material for specialized and demanding applications.

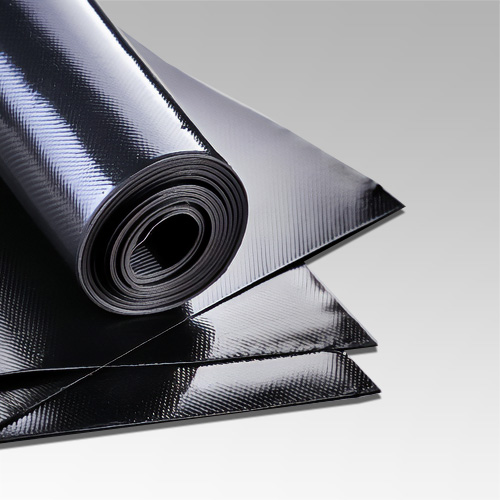

Fiberglass

Fiberglass is a highly versatile and durable composite material that combines the strength of glass fibers with the resilience of resin. Its high strength-to-weight ratio, corrosion resistance, and excellent insulating properties make it suitable for a wide range of applications, from construction and automotive to marine to wind energy.

Fluorosint

Fluorosint® is a family of high-performance, reinforced polytetrafluoroethylene PTFE materials known for their enhanced mechanical and thermal properties. Developed by Quadrant Engineering Plastic Products now part of Mitsubishi Chemical Advanced Materials, Fluorosint® offers a unique combination of properties that make it suitable for demanding applications where conventional PTFE may not perform adequately.

Glass Silicone

Glass silicone is a versatile, durable, and flexible material ideal for a wide range of sealing and bonding applications involving glass and other smooth surfaces. Its excellent adhesion, weather resistance, and thermal stability make it a preferred choice in construction, automotive, electronics, and DIY projects.

GPO

GPO is available in many grades including T-160 high strength, SG-200, and more. GPO materials are made from fiberglass blended with a polyester resin. The result is materials that offer excellent ark and track resistance. They are used throughout industries for electrical applications requiring strength and impact resistance. GPO come in several grades and are selected based on the needs of a particular application. They are available in sheet, rod, tube and shapes.

GPO-2

GPO-2 plastic is a good general purpose, cost-effective plastic. It is flame-retardant grade for I.E.E.E. temperature class 130°C and meeting NEMA making it ideal for applications requiring arc or flame resistance. GPO-2 is commonly used for high amperage mounting panels, arc shoot components, switch bases, and more.

GPO-3

GPO-3 NEMA grade sheet is a highly flame-resistant material made from a blend of fiberglass reinforced thermoset polyester. GPO-3 plastic sheet is a UL is a UL®-recognized material for electrical insulation applications thanks to its highly flame-retardant characteristics and arc/track resistance. Popular for use in transit and marine applications where high strength, flame resistance, and low smoke generation is required. GPO-3 grade sheet in standard sizes are available. Custom sizes available upon request to meet the needs of your specific application.

HDPE

High density polyethylene HDPE offers superior corrosion resistance, a higher working temperature range, and higher tensile strength over Low density polyethylene LDPE. HDPE outperforms low density polyethylene in both physical and chemical properties. However, HDPE is less flexible than low density polyethylene. HDPE is FDA compliant as well as USDA and NSF standards. Outdoor exposure is similar to low density polyethylene.

Common uses include food processing applications. Thin gauge sheets are popular in silk screen, offset lithography and foil stamping applications. It is also used in municipal water systems. HDPE make an excellent wear strip material due to its long life and smooth surface.

HMW

High Molecular Weight HMW plastic, specifically referring to High Molecular Weight Polyethylene HMWPE, is a type of polyethylene that has a higher molecular weight compared to standard polyethylene materials. This increased molecular weight results in enhanced physical properties, making HMWPE suitable for more demanding applications. It is commonly used for packaging, industrial equipment, agriculture, marine, automotive, construction, and recreation purposes.

Hydex

Hydex® is a brand name for a family of high-performance engineering thermoplastics, specifically polyetheretherketone PEEK and other specialized materials, developed by Ensinger. These materials are designed to offer superior mechanical and thermal properties, making them suitable for demanding applications in various industries, including aerospace, automotive, medical and pharmaceutical, food processing, oil and gas, industrial equipment, and electronics.

Hydlar

Hydlar® is a high-performance nylon composite reinforced with aramid fibers, offering superior strength, wear resistance, and low friction. These properties make it an excellent choice for demanding applications in the automotive, aerospace, industrial machinery, marine, and textile industries. Hydlar's versatility and reliability make it a valuable material for high-stress, high-wear environments.

Kemlite

Kemlite, recognized under the Crane Composites brand, continues to set the standard in the production of fiberglass-reinforced plastic FRP panels. These panels are engineered to withstand rigorous environments, providing exceptional performance in settings that demand high hygiene standards, durability, and moisture resistance. From commercial kitchens to industrial facilities, Kemlite FRP panels are prized for their robustness and ease of maintenance. Their adaptability extends to both interior and exterior applications, offering solutions that are not only functional but also aesthetically pleasing with a variety of finishes and textures. Furthermore, the lightweight nature of these panels simplifies installation and reduces overall labor costs, making them an attractive option for large-scale construction and renovation projects. With a commitment to quality and innovation, Crane Composites continues to enhance the Kemlite product line, ensuring that their FRP panels meet the evolving needs of diverse industries.

KYNAR PVDF

Kynar® PVDF Polyvinylidene Fluoride is a high-performance thermoplastic known for its exceptional chemical resistance, thermal stability, and durability. It is widely used in various demanding applications due to its unique combination of properties.

LDPE

Low density polyethylene LDPE is an extruded engineered plastic that offers good corrosion resistance properties and low moisture permeability. It can be used in applications where corrosion resistance is a factor, but stiffness, high temperatures, and structural strength are not. For these applications, refer to its counterpart, high density polyethylene HDPE. LDPE is easy to fabricate, vacuum form, and weld. In applications requiring low temperature flexibility, toughness, and durability, LDPE can be an excellent cost effective option.

Noryl

Noryl® is a versatile and high-performance family of modified polyphenylene ether PPE resins that combines thermal stability, mechanical strength, electrical insulation, and chemical resistance. These properties make it suitable for a wide range of applications in the electrical, automotive, industrial, appliance, telecommunications, and medical sectors. Overall, Noryl®'s balanced performance characteristics make it a valuable material for engineering and industrial applications.

Nycast

Nycast® is a brand of Cast Nylon 6 material manufactured by Cast Nylons Limited. Cast Nylon 6, one of the oldest and most widely used machinable plastics, is a synthetic polymer known for its exceptional strength, toughness, and resistance to wear and abrasion. Nycast® is used as an alternative to metals such as bronze, brass, steel, and aluminum across various industrial sectors including construction equipment, food processing systems, and transportation. As opposed to traditional metals used in component parts, Nycast® materials offer longer component life, lower maintenance cost, better chemical and corrosion resistance, the elimination of external lubrication, improved service life, and noise reduction.

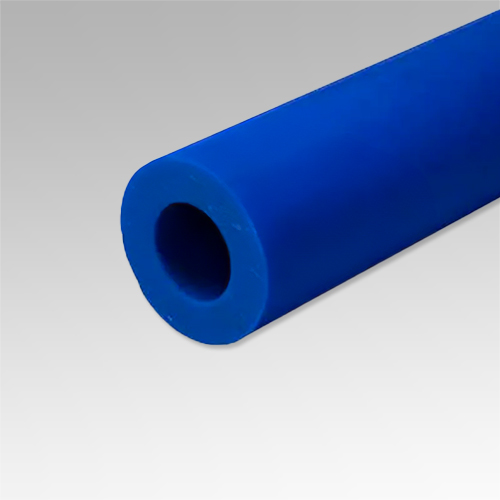

Nylaflow

Nylaflow® Nylon Tubing is durable and high-performance pressure tubing suited for applications that require flexibility, tight bending capabilities, and exceptional burst resistance. Compared to common alternatives such as vinyl, ethylene, and urethane tubing, Nylaflow® is longer-lasting and more resistant to wear and abrasion. Additionally, Nylaflow® has excellent chemical resistance and can withstand exposure to relatively high concentrations of harsh chemicals at elevated temperatures. Commonly used in airline systems, pneumatic and hydraulic operations, grease transfer lines, and vacuum setups, Nylaflow® is a versatile solution trusted for its resilience and reliability in demanding environments.

Nylatron GS

Nylatron GS is a high-performance, molybdenum disulfide-filled nylon material that offers superior mechanical properties, wear resistance, and low friction compared to standard nylon. It is widely used in applications that demand high strength, durability, and reliable performance under dynamic loads and high temperatures. Common applications include gears, bearings, bushings, wear pads, rollers, and various automotive and industrial components.

Nylatron GSM

Nylatron GSM is a high-performance, molybdenum disulfide-filled nylon material that offers superior mechanical properties, wear resistance, and low friction compared to standard nylon. It is widely used in demanding applications that require high strength, durability, and reliable performance under dynamic loads and high temperatures. Nylatron GSM offers superior tensile and compressive strength, greater wear resistance, and better dimensional stability, making it ideal for heavy-duty applications that require high load-bearing capacity and durability under demanding conditions. Common applications include gears, bearings, bushings, wear pads, rollers, and various automotive and industrial components.

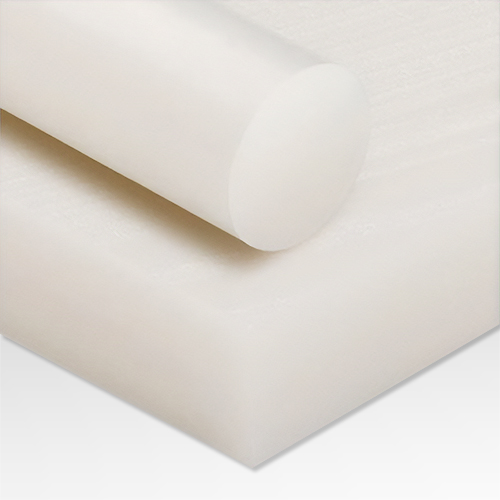

Nylon

Nylon is a synthetic polymer valued for its toughness, elasticity, and resistance to abrasion. It serves as a high-performing alternative to metal parts and assemblies, providing corrosion resistance, ease of cleaning, non-contamination in food manufacturing processes, and longevity in high-speed manufacturing environments.

PEEK

Polyetheretherketone, also known as PEEK, is a high-performance engineered plastic that is uniquely suited to extreme environments, providing advanced resistance to harsh chemicals while exhibiting outstanding dimensional stability and mechanical strength. PEEK has hydrolysis resistance and the ability withstand exposure to extreme temperatures – up to 249°C 480°F in continuous use. Due to its unique characteristics that allow it to perform well in extreme environments, PEEK plastic is commonly used for demanding applications in various industries including aerospace, chemical & gas, healthcare, filter manufacturing, pharmaceutical, and food and beverage.

PET

PET Polyethylene Terephthalate is a widely used thermoplastic polymer known for its versatility, transparency, mechanical strength, and recyclability. It finds applications across various industries, including packaging, textiles, electronics, and automotive, due to its favorable combination of properties and cost-effectiveness.

Phenolic

Phenolic resins are highly versatile synthetic polymers known for their thermal stability, mechanical strength, and chemical resistance. They find widespread use in automotive, construction, electronics, aerospace, and industrial applications where durability, fire resistance, and reliability are paramount.

Polycarbonate

Polycarbonate PC is a clear, exceptionally high impact material. It possesses good dimensional stability and rigidity. In addition it has high tensile strength, is resistant to chemicals and it is self-extinguishing. The properties of polycarbonate make it ideal for numerous applications and industries.

Polycarbonates diverse balance of properties combine exceptional toughness with low and high temperature capabilities. Polycarbonate can be formulated to meet the most demanding needs of industrial component manufacturers or exacting aerospace and military applications. Flame inhibiting grades are used for electrical and electronic device applications such as switchgear covers, current carrying components and thermoformed equipment housing.

In architectural applications polycarbonate is used for covered walkways, barrel vaults, bus shelters and glazing. Bullet resistant polycarbonate is available and is a common choice for store windows. Polycarbonate is available with coatings for added UV stability, scratch resistance and more. It is also available in an FDA compliant grade.

Polypropylene

Polypropylene is available in several grades and under the following names:

Proteus Co-Polymer - High impact resistant thermoplastic with excellent resistance to cracking at low temperatures. The co-polymer is more pliable than the homopolymer. Additionally it is FDA compliant, chemical and corrosion resistant and has no moisture absorption.

Proteus Homopolymer - Appropriate for applications to 180°F 82°C, Homopolymer resists most acids, alkalis and solvents Proteus homopolymer meets FDA 21CFR 177.1520 and USDA guidelines for use in federally inspected meat and poultry packing facilities. It is chemical and corrosion resistant.

Proteus O&P Grade - Thermoforming performance, Used for orthotic & prosthetic applications, Rigid form of polypropylene used where high stiffness is required, Typical Flexural Modulus: 195,000 PSI, Lot-to-lot consistency and formability, Chemical- and corrosion-resistant, No moisture absorption.

Proteus Premium Gloss - Film masked 1 side 2 sides available in white only, Thermoforming performance, Meets FDA requirements for food contact, Reg. 21CFR177.1520, Rigid, Light-weight, Resists stress cracking, Easily fabricated, High impact strength, Good Electrical properties.

Sanalite - NSF certified under Standard 02, Meets FDA Regulation 21CFR177.1520 Item 2.1, USDA compliant, Ag Canada approved, Pebbled surface resists acids, Easily cleaned, Lightweight, Chemical- and corrosion-resistant, No moisture absorption.

PTFE

Polytetrafluoroethylene PTFE is a high-performance fluoropolymer known for its non-stick properties, chemical resistance, thermal stability, and excellent electrical insulation. These characteristics make it a versatile material used in various industries, including cookware, chemical processing, electronics, aerospace, medical devices, automotive, and industrial machinery. PTFE's unique properties provide significant advantages in terms of durability, performance, and safety, making it a valuable material for demanding applications.

PVC

PVC polyvinyl chloride is a synthetic plastic polymer used in industrial applications including pipes, valves, processing tanks, and plumbing, electrical cable insulation and more. Expanded PVC is used for signage and displays. PVC has many exceptional properties that make it an ideal choice for your industrial applications.

PVC Polyvinyl Chloride sheet combines wide ranging performance characteristics to meet the design needs of many applications. PVC sheet is easily welded and forms a strong bond when finished.

PVDF

Polyvinylidene fluoride PVDF is a high-performance thermoplastic known for its exceptional chemical resistance, mechanical strength, thermal stability, and UV resistance. These properties make it ideal for demanding applications in chemical processing, electrical and electronics, water treatment, construction, oil and gas, medical devices, and aerospace industries. Its low coefficient of friction makes it suitable for applications requiring smooth, low-wear surfaces, such as in bearings and seals.

Radel

Radel® PPSU is a high-performance thermoplastic known for its exceptional temperature resistance, toughness, chemical resistance, and hydrolytic stability. These properties make it ideal for demanding applications in the medical, aerospace, automotive, food processing, electronics, and plumbing industries.

Rexolite 1422

Rexolite® 1422 is a high-performance cross-linked polystyrene copolymer known for its low dielectric constant, low dielectric loss, high mechanical strength, and optical clarity. These properties make it especially suitable for high-frequency and microwave applications, including antennas, waveguides, medical imaging devices, and aerospace components.

Rulon

Rulon® is a versatile family of high-performance PTFE compounds known for their exceptional wear resistance, low friction, and broad chemical resistance. These materials are ideal for demanding applications in various industries, including automotive, aerospace, industrial machinery, and medical devices, where durability, reliability, and reduced maintenance are essential.

Semitron

The Semitron® ESd line of static dissipative products is engineered to tackle electrical discharge challenges often faced by delicate electronic components. Commonly utilized in integrated circuits, hard drive disks, and circuit boards, these products also excel in material handling applications and high-speed electronic printing equipment. Unlike many other "dissipative" plastic shapes, Semitron® ESd products boast inherent dissipative properties and electrical stability. They don't rely on atmospheric conditions or surface treatments for dissipation; instead, static electricity is swiftly discharged through these products.

Tecapeek

TECAPEEK is a brand name of Polyetheretherketone PEEK, manufactured by Ensinger. It is a high-performance, high-temperature, semi-crystalline thermoplastic renowned for its resilience in extreme conditions. TECAPEEK offers superior resistance to harsh chemicals, resistance to hydrolysis, and can withstand temperatures up to 260°C 500°F. Additionally, TECAPEEK delivers exceptional mechanical strength and dimensional stability under thermal stress, making it a preferred choice for demanding applications across various industries.

Techtron

Techtron® PPS is a high-performance thermoplastic known for its exceptional mechanical strength, thermal stability, and chemical resistance. These properties make it ideal for demanding applications in the automotive, aerospace, electrical and electronics, industrial machinery, chemical processing, and oil and gas industries.

Teflon FEP

Teflon® FEP is a high-performance fluoropolymer known for its outstanding chemical resistance, non-stick properties, thermal stability, and excellent electrical insulation. These attributes make it ideal for a wide range of applications, including wire and cable insulation, chemical processing, medical devices, food processing, electronics, and aerospace components.

Teflon PTFE

Teflon™ PTFE Polytetrafluoroethylene is a synthetic fluoropolymer of tetrafluoroethylene. It is a high-performance material utilized for its non-stick properties, chemical resistance, and high temperature resistance. PTFE is non-reactive to most chemicals, highly resistant to corrosion, and has a wide operating temperature range from -200°C to +260°C -328°F to +500°F. Due to these properties, Teflon™ PTFE is widely used in various industries for applications such as seals, gaskets, bearings, electrical insulation, and non-stick coatings for cookware.

Thordon

Thordon® is a high-performance family of water-lubricated polymer bearing materials known for their wear resistance, low friction, and environmental friendliness. These materials are widely used in marine, hydropower, pump, and industrial applications where water lubrication is beneficial. Thordon bearings provide long service life, reduce maintenance costs, and minimize environmental impact by eliminating the need for oil and grease lubricants.

Torlon

Torlon® PAI is a high-performance thermoplastic known for its exceptional mechanical strength, thermal stability, and chemical resistance. These properties make it ideal for demanding applications in aerospace, automotive, industrial machinery, oil and gas, electrical and electronics, and medical devices.

UHMW Polyethylene

Ultra-high molecular weight polyethylene UHMW or UHMW-PE is a lightweight and durable engineering plastic material. UHMW Polyethylene is a self-lubricating, chemically inert thermoplastic with a very low coefficient of friction, excellent abrasion and wear resistance, and high resistance to chemicals and impact. Many variations are suitable for food contact, provide static dissipation, and are UV resistant. UHMW Polyethylene is an ideal choice for numerous industrial and food processing applications. Common uses include machined parts for conveyors, packaging equipment, and metal part replacements such as chutes, wear strips, guides, and rollers, particularly in wet environments.

Ultem

Ultem® is a high-performance thermoplastic polyetherimide PEI renowned for its exceptional mechanical strength, thermal stability up to 170°C 338°F, and chemical resistance to acids, alcohols, and hydrocarbons. Developed by SABIC, it is widely used in aerospace, automotive, and industrial applications where durability, flame retardance UL 94 V-0 rated, and reliability are crucial. Ultem®'s properties also make it suitable for medical devices, food processing equipment, and electronics, thanks to its dimensional stability, low shrinkage, and transparency options in certain grades. Despite its higher cost, Ultem®'s robustness and versatility make it a preferred choice for demanding environments across various industries.

UPVC

uPVC stands for unplasticized Polyvinyl Chloride, which is a rigid and chemically resistant form of PVC. Unlike traditional PVC, uPVC does not contain plasticizers, making it more durable and suitable for a wider range of applications. It is highly regarded in the construction industry for its ability to withstand harsh environmental conditions, including UV radiation, moisture, and fluctuating temperatures, without significant degradation.

Urethane

Urethane, or polyurethane PU, is a versatile polymer known for its durability, flexibility, and wide range of applications across industries such as construction, automotive, furniture, and footwear. With properties that include excellent abrasion resistance, weather resistance, and adhesion capabilities, urethanes can be tailored to meet specific performance needs in coatings, adhesives, foams, elastomers, and molded parts.